Industry 4.0: new talent for a new factory

To face the digitalization, sustainability and robotization of the factories, the profile of the workers is also transformed becoming increasingly evident the appearance of new tasks and new profiles.

The fashion industry, a sector that has barely evolved in thousands of years, now faces a profound transformation. The new consumption habits, the new socio-economic and geopolitical scenario, the demographic changes and the irruption of technology in all daily tasks also have an impact on the value chain of the sector. Digitization and sustainability open a new era in all its links, which implies the incorporation of new systems in the factories. Itma, the largest fair of textile machinery, will give the keys of what will be the fashion industry of the future in its next edition, which will be held from 20 to 26 June at Fira de Barcelona. There will be 1,600 exhibitors and it is expected to exceed 125,000 visitors.

The irruption of the digital era have an impact on the staff. The profile of workers is transformed while new tasks appear in industrial companies. In the same way that it happens in the rest of the economic sectors, the digitalization supposes a challenge in the organizations whose resolution happens one way or another by the formation. The industry does not escape data analysis, online channel management, digital traffic control, mobile applications or content creation.

The transformation towards digitalization goes beyond changing blue coats by white coats. In the textile header, the most technologically advanced of the value chain, the automation of processes and even robotization is a reality. The challenge now is the management of the data and the ability to share it with the rest of the actors. Hence, even in the factory, it is not unreasonable to find chief data officers and chief information officers, data analysts or chief experience officers, among others.

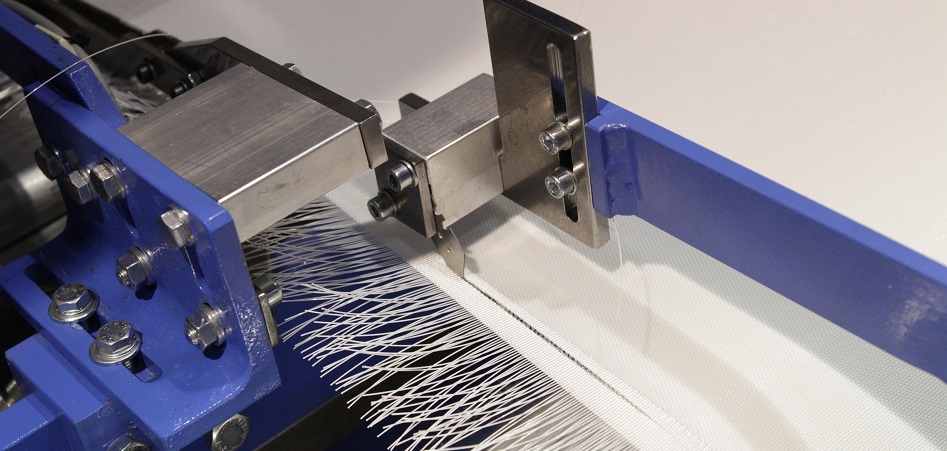

The processes of spinning, weaving, dyeing and finishing in the European Union have long since technified their processes. During the decades of crisis, the companies that opted to maintain the business in the territory made their survival dependent on technological investment as the only way to reduce costs, advance the development of new products and minimize the impact on the environment, against the toughening of European legislation in this regard.

The textile head, which automated processes in the last three decades, is the fashion subsector that has created the most jobs in Spain since 2014

Despite the automation, the header textile has been the one that has taken the lead of the employment of the whole industry of the fashion in the last years. Between January 2014 and January 2019, Social Security affiliates in this category have grown by 14.3%, to a total of 46,853 workers, according to data from the Spanish Ministry of Labor, Migration and Social Security.

In the case of clothing, traditionally much more labor-intensive, the advance in employment in this same period has been 3.2%, up to 48,954 workers. The distance between affiliates in textiles and clothing has drastically shortened. In this way, although January 2014 the garment industry had around 7,000 more workers than the textile industry; five years later it adds only one thousand more.

In the same way that automation has contributed to the textile industry generating employment, and in addition to higher quality, it is expected that digitalization will advance in the same direction. In the next edition of the Itma fair, of textile machinery, all the products that are exposed will have sensors to extract data, which must be analyzed, interpreted and used, both for the internal management of the factory and to exchange them with other actors.

The manufacturers of textile machinery have enriched their staff in the last decade with computer engineers to develop the new software that will help this reading. The manufacturing capacity of machines is now given for granted, because the value lies in all the data they can generate and the ability to take advantage of them.

The confection, a step behind

From the whole of the value chain, clothing is the only link that is still intensive even in labor. The automation of sewing came alongside with spinning or weaving, in the last third of the last century, but the emergence of new production poles in Asia with very low costs discouraged investment in the technification of garment factories in Europe and the United States. But this supply formula has no route.

In Ethiopia, the last mecca of low cost production, the new factories destined to garment manufacture begin to incorporate the first automated sewing systems. In China, investment in new factories composed only of sewing robots is growing by leaps and bounds. For the moment, they only concentrate on the production of mono-product, like white shirts.

According to industry experts, there is no turning back on the automation of the clothing or the social impact that may cause in some of the most fragile economies on the planet. To contain the social impact, it is expected that countries like Bangladesh, Vietnam, Cambodia or even Myanmar or Ethiopia begin to diversify their industrial structure with sectors of higher added value, as China did a decade ago.

While waiting for the automation of the confection, digitization has also been introduced in its process. The union between retailers and garment manufacturers has been reinforced as they have been interconnecting data. The first scores of personalization in the distribution have meant a leap forward in this sense with a view to gaining speed and efficiency. And in this equation, the proximity to the consumer markets will once again play a determining role.

New profiles

The Business Council for Competitiveness indicated in the Spain 2018 report the positions that will have a greater demand in the development of the digital economy, not only in the industry but in all companies. The biggest challenge for companies in the fashion value chain is not knowing how a digital printer works, a 3D or even a robotic arm for sewing shirts, but managing the avalanche of data that comes with the new era.

In this way, the main one will be chief digital officer, responsible for the digital transformation of the company, with a complete vision of the digital business. It will be followed by the chief information officer, responsible for information technology; the director of digital innovation, able to hybridize the traditional tasks with which digitalization entails; the data scientist, who knows the technological architecture of the business; the director of cybersecurity; the head of smart factory, or the director of digital talent, among others.

info@themds.com

Validation policy for comments:

MDS does not perform prior verification for the publication of comments. However, to prevent anonymous comments from affecting the rights of third parties without the ability to reply, all comments require a valid email address, which won’t be visible or shared.

Enter your name and email address to be able to comment on this news: once you click on the link you will find within your verification email, your comment will be published.